Email tsis tuaj yeem khoob

Tus password tsis tuaj yeem khoob

Email format yuam kev

Email tsis tuaj yeem khoob

Email twb muaj lawm

6-20 cim (tsuas ntxiv cov lej xwb)

Tus password tsis sib xws

Email format yuam kev

Email tsis tuaj yeem khoob

Email tsis muaj

6-20 cim (tsuas ntxiv cov lej xwb)

Tus password tsis sib xws

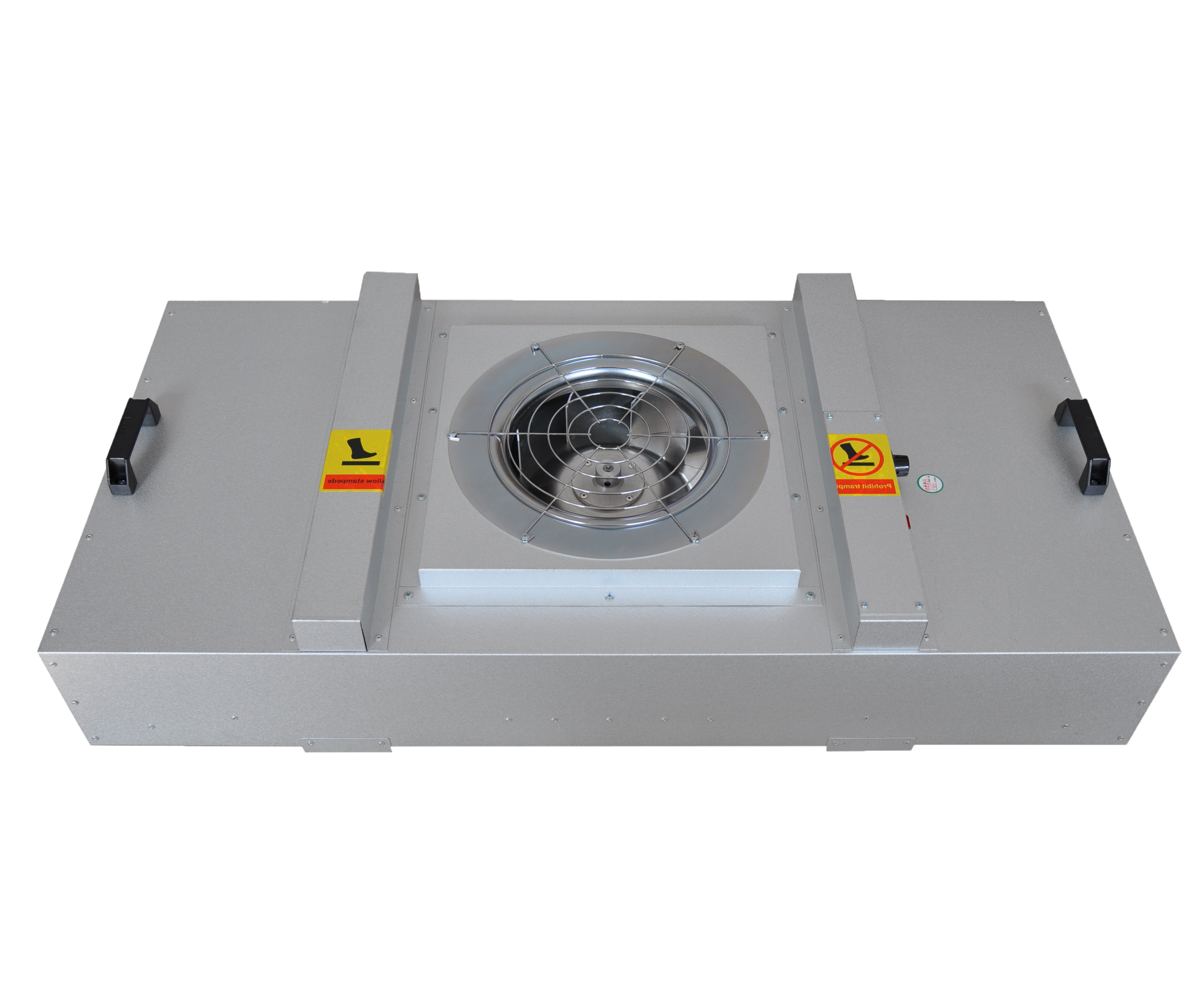

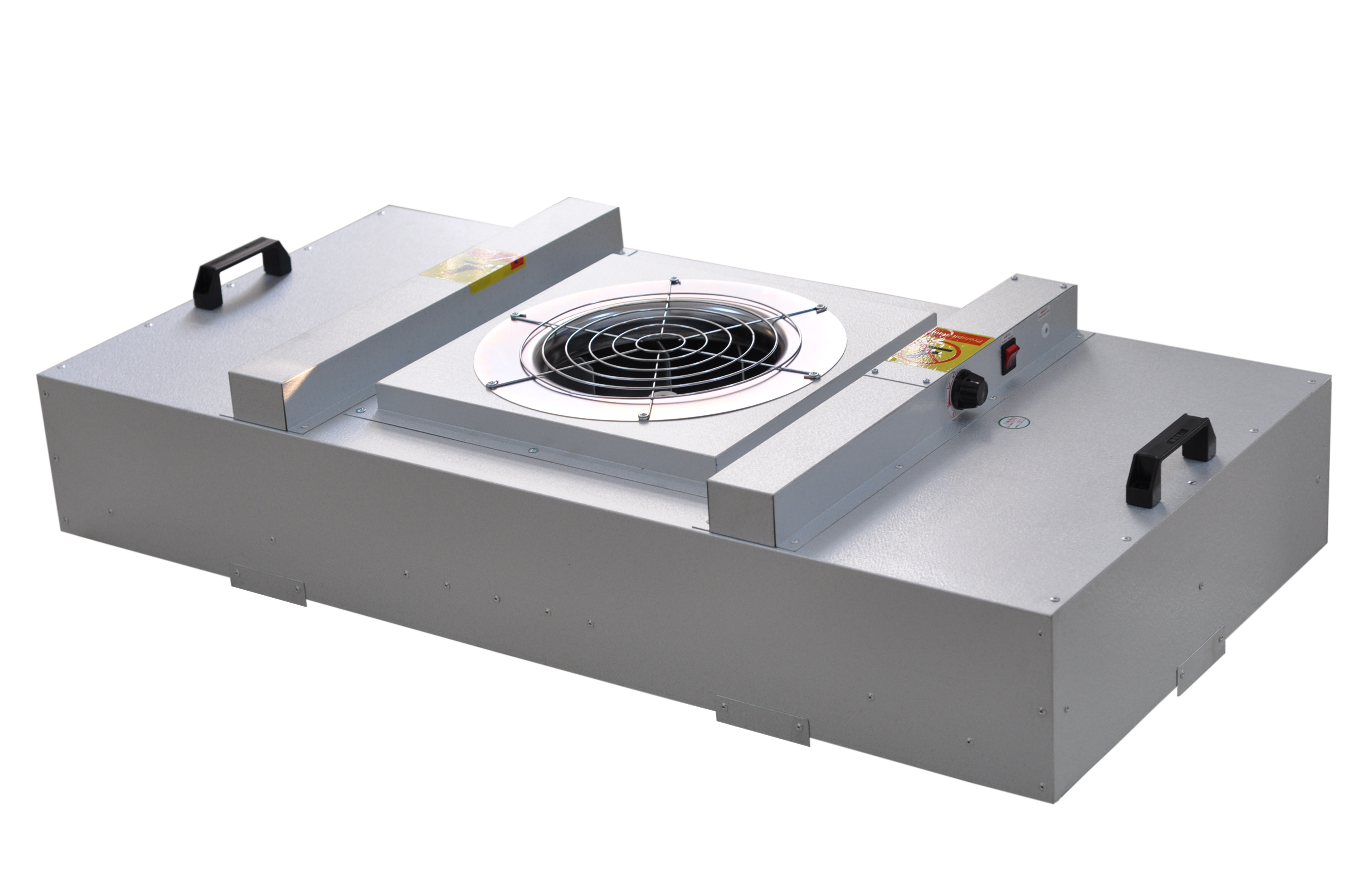

Tawg tawg-pov thawj Fan Kev Kub (FFU)

Qhov kev ua haujlwm deshengxin tawg-pov thawj tshuab lim (FFU) Cov khoom lag luam tshiab ua ke sib xyaw ua ke tawg-pov thawj kev tsim kho cov khoom siv huab cua siab thiab ua haujlwm tau zoo hauv kev xav tau ib puag ncig. Cov yam ntxwv thiab cov txiaj ntsig: 1. Kev tsim qauv ua pov thawj: pov thawj FFU ua cov khoom siv uas tuaj yeem tiv thaiv cov pob zeb ntawm cov cua sov. Nws ua raws nrog kev tawg thoob ntiaj teb-ntawv pov thawj, muab ib qho kev thaiv kev txhim kho tiv thaiv kab ntxwv, cua sov, thiab cov roj av / plua plav sib xyaw. 2. Kev ua haujlwm siab ua haujlwm: ua ke nrog cov lim dej siab (ulpa, lossis lwm cov qib, ua xua, thiab cov pa phem los ntawm huab cua. Qhov no kom ntseeg tau tias huab cua huab cua ncig hauv cov chaw muaj kev phom sij tau ntsib nruj kev nyab xeeb thiab cov qauv zoo. 3. Lub zog, tawg-pov thawj-pov thawj Tus kiv cua yog tsim los txo suab nrov thiab kev co, kom muaj kev sib tw ntawm cov huab cua ruaj khov thiab txhim khu kev qha. 4. Kev kho yooj yim thiab servriceability: txawm tias nws muaj kev tsim kho tshwj xeeb, pov thawj ffu yog tsim rau kev yooj yim txij nkawm. Cov lus lim yuav nkag tau thiab hloov sai thiab nyab xeeb, txo qis downtime thiab khaws cov nqi kev ua haujlwm qis. 5. Kev daws teeb meem kev daws teeb meem: Pom txog ntau yam kev xav tau ntawm cov chaw muaj kev phom sij rau cov kev xaiv customization rau kev tawg-pov thawj ffu. Los ntawm lim xov xwm xaiv rau cov neeg ntxaij thiab mounting kev teeb tsa, peb ua haujlwm ze nrog cov neeg siv khoom tsim cov kev daws teeb meem uas tau raws li lawv cov kev xav tau tshwj xeeb. 6. Lub neej thiab kev ntseeg tau: tsim los ntawm cov ntaub ntawv zoo thiab raug kom nruj kev ntsuas kev ua kom nruj, cov khoom lag luam deshengxin tawg-ua pov thawj ffu. Nws cov kev ua tau zoo txhim khu kev ua kom ua kom cov pa huv txuas ntxiv, txawm tias cov mob xav tau tshaj plaws. Cov ntawv thov: The Deshengxin tawg-pov thawj ua kom muaj cov khoom lag luam roj thiab cov roj av ua haujlwm cov kuab tshuaj tua cov haujlwm Cov khoom siv hluav taws xob ntau rau lwm qhov chaw uas yog cov khoom siv lim dej (FFU) yog qhov ua pov thawj Nws tawg-pov thawj kev tsim kho, muaj txiaj ntsig zoo ua rau nws muaj qhov kev xaiv zoo tshaj plaws rau cov kev siv muaj kev lag luam. Ntseeg deshengxin los muab koj muaj kev nyab xeeb, txuag, thiab txhim kho huab cua txhim khu kev qha rau koj ib puag ncig kev puas tsuaj.

The Deshengxin Explosion-Proof Fan Filter Unit (FFU) is a pioneering solution tailored for the stringent requirements of hazardous industrial environments. This advanced air purification system combines unparalleled safety features with superior filtration capabilities, ensuring clean, safe air circulation in areas where flammable or explosive materials are present.

Core Features:

1. Explosion-Proof Construction:

The FFU's housing is constructed from explosion-proof materials that can withstand extreme conditions, including high temperatures, sparks, and ignitable gas/dust mixtures.

It complies with international standards for explosion-proof electrical equipment, such as ATEX or IECEx, ensuring compliance with regional safety regulations.

2. High-Efficiency Filtration Technology:

Equipped with high-grade filters (HEPA, ULPA, or custom specifications), the FFU removes airborne particles, dust, allergens, and pollutants with exceptional efficiency.

The filters are designed to trap even the finest particles, providing a clean and safe working environment for personnel and protecting sensitive equipment from contamination.

3. Powerful Explosion-Proof Fan:

The integrated fan is specially designed to operate safely in explosive atmospheres, providing a steady and controllable airflow throughout the hazardous area.

The fan is engineered for low noise and vibration levels, ensuring a smooth and uninterrupted operation that doesn't disrupt the surrounding environment.

4. Easy Maintenance and Service:

The Deshengxin Explosion-Proof FFU is designed for ease of maintenance, with accessible filter compartments that allow for quick and safe filter replacement.

Regular maintenance is straightforward, minimizing downtime and keeping operational costs low.

5. Customizable Solutions:

Understanding the diversity of hazardous environments, Deshengxin offers a range of customization options for the Explosion-Proof FFU.

From filter size and grade to fan specifications and mounting configurations, we collaborate with customers to create tailored solutions that perfectly match their specific needs.

6. Durability and Reliability:

Manufactured from high-quality materials and subjected to rigorous quality control tests, the Deshengxin Explosion-Proof FFU is built to withstand the harshest conditions.

Its reliable performance ensures continuous air purification, safeguarding personnel, equipment, and processes in even the most demanding hazardous environments.

Applications:

The Deshengxin Explosion-Proof FFU is widely applicable in various industries where the risk of explosion or ignition is present, including:

- Petrochemical and chemical processing plants

- Oil and gas refineries

- Paint shops, coating facilities, and surface treatment centers

- Solvent-based manufacturing operations

- Pharmaceutical and biotechnology facilities with solvent or flammable material handling

- Mining operations with explosive atmospheres

- Any other area where the risk of ignition from airborne particles or gases exists

Conclusion:

The Deshengxin Explosion-Proof Fan Filter Unit (FFU) represents the cutting edge of air purification technology for hazardous industrial environments. Its robust explosion-proof design, high-efficiency filtration, and customizable features make it an indispensable tool for maintaining safe and clean air circulation in the most challenging settings. With Deshengxin, you can trust that your air purification solution is not only effective but also fully compliant with international safety standards.

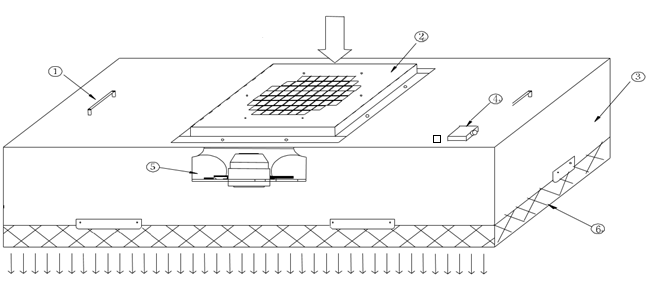

FFU Assembly diagram

|

1 |

|

5 |

Motor |

|

2 |

|

6 |

HEPA filter |

|

3 |

|

|

|

|

4 |

|

|

|

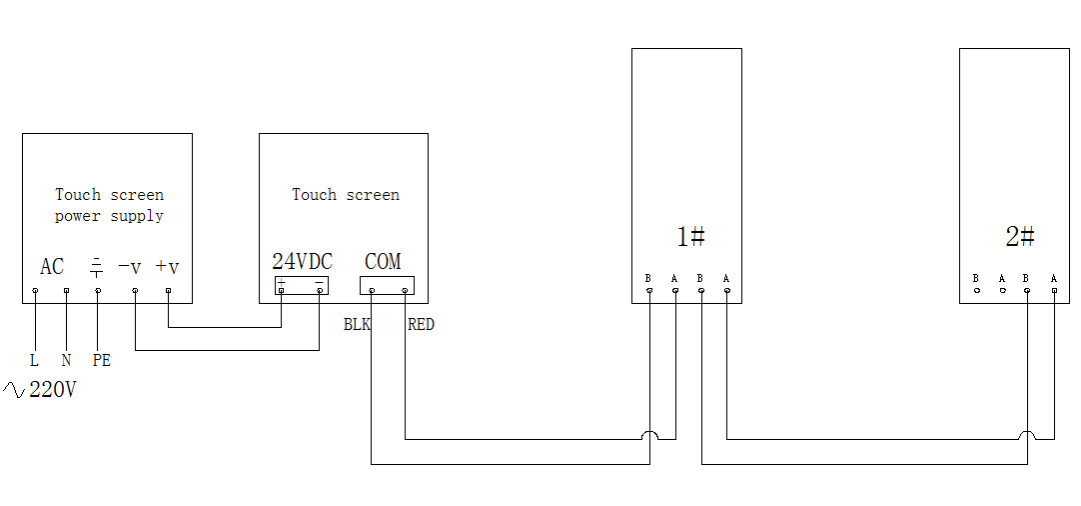

FFU Wiring diagram (Group control)

DSX FFU Introduction

Versatile FFU Systems with Customizable Materials, Motors, and Controls

Materials for ontology that can be used as an option such as steel plate paint stainless steel 304, 316 Aluminum plate Optional several efficient AC/DC motorsIndividually controlled and centrally via a computer network. It can also be monitored remotely

Filters are made from fiberglass, PTFE, or are available using HEPA, ULPA filters of various levels of filtration.

Effective and quiet FFU Systems that are Space-Saving Design and a Stable Airflow.

DSX FFU uses an easy and light design which saves space and facilitates installation and maintenance.The particular design of the air intake and air conduit layout reduces noise, vibration, and noise production.

The internal diffuser plate provides an even air pressure distribution and stability of wind speed at the outlet.

Customizable FFU Systems with Energy-Efficient Motors

It is powered by a high-efficiency motor that can be adjusted to three speeds and low power consumption and low operating expenses (DC motors are also chosen to save energy). The motor was developed and manufactured by DSX and is able to be adjusted in accordance with the needs of the customer.

Versatile FFU Systems with Multiple Filter Options for Superior Filtration

Filter materials could be fiberglass, PTFE or optional HEPA and ULPA filtering systems with various filtering levels. Filter grade options include H13, U14 U15 and U16.

Perfect for special events

In addition to FFUs that are used in normal situations, we also offer FFUs that are specifically designed for industries that use lithium batteries, extremely thin FFUs for spaces with limited space, and explosion-proof FFUs. As a leading FFU producer, we are able to customize FFUs to suit various situations for our customers.

Make sure you are in a clean area

Each of DSX FFUs is assembled in cleanrooms to guarantee an extremely clean environment. Our FFUs strictly follow the strictest guidelines and adhere to cleanroom procedures throughout the production process. This strict approach ensures we can guarantee that the FFUs are clean of any contamination, which is essential to ensure optimal performance while maintaining clean working environments across a variety of applications.

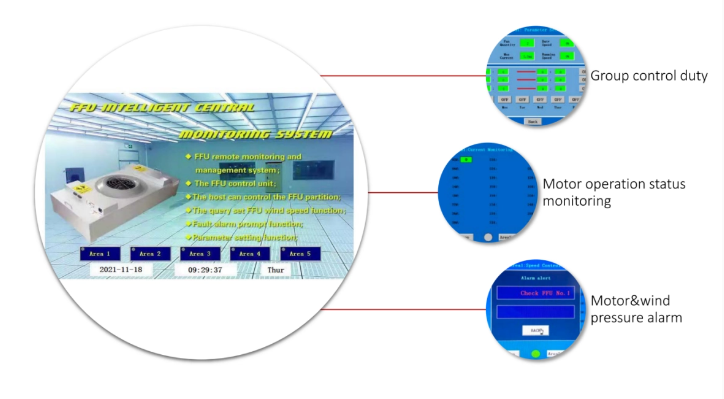

Customizable FFU Control System: Enhancing Efficiency and Performance

We have developed our FFU control system was developed and created by our own engineers, offering unparalleled flexibility and customization. With attention to particulars the control system we use offers an array of customizable options to satisfy specific customer needs. If it's creating the interface for control, altering rates of baud, or choosing the preferred option for display language Our control system is able to be customized to meet different communication styles and requirements of the customer. This flexibility allows for an easy integration into existing systems, and increases the overall effectiveness and efficiency for our FFUs.

Deshengxin FFU Regular parameters

| DESCRIPTION | Size(L*W*HMM) (Including HEPA) |

Air velocity (m3/h) |

Air flow (m/s) | Noise | Position of testing noise | Shell material | Power Supply | Rated power |

| Ultra thin FFU | 1175*575*180 | 1000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.17kw |

| FFU575575 | 575*575*320 | 500 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU615615 | 615*615*320 | 700 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU915615 | 915*615*320 | 900 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU1175575 | 1175*575*320 | 1000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU1175*1175 | 1175*1175*350 | 2000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.18kw |

The size and other parameters can be customized according to the clients' demands.

1.FFU parameters(CE):

|

Model |

DSX-FFU01-02 |

DSX-FFU01-02 |

DSX-FFU01-03 |

DSX-FFU02-02 |

DSX-FFU02-04 |

|

FFU dimension (mm) |

575 x 575 x 210 |

1175 x 575 x 210 |

1175 x 575 x 270 |

1175 x 1175 x 270 |

1175x1175x210 |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

||||

|

Fan |

AC |

||||

|

Input |

230ACV/60HZ/1P |

||||

|

Speed (m/s) |

0.45~1 m/s±20% at high speed |

||||

|

Control type |

Manual |

||||

|

HEPA Height (mm) |

50 / 70 Optional |

||||

|

HEPA filter material |

Glass fibre |

||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||

|

Operating temperature |

10~40℃ |

||||

|

Structure type |

Split type |

||||

|

Installation mode |

Horizontal / Vertical |

||||

2. FFU parameters(Ultrathin type):

|

Model |

Ultrathin type |

|||

|

FFU dimension (mm) |

875X575X160 |

1350X460X160 |

1600X460X160 |

Other dimension |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|||

|

Fan |

AC / EC |

|||

|

Input |

220ACV/50HZ/1P |

|||

|

Speed (m/s) |

0.45~0.7 m/s±20% at high speed |

|||

|

Control type |

Manual / RS485 |

|||

|

HEPA Height (mm) |

50 / 70 Optional |

|||

|

HEPA filter material |

Glass fibre |

|||

|

HEPA efficiency |

H13 / H14 /U15 |

|||

|

Operating temperature |

10~40℃ |

|||

|

Structure type |

Split type |

|||

|

Installation mode |

Horizontal / Vertical |

|||

3.FFU parameters(Conventional type):

|

Model |

Conventional type |

||||

|

FFU dimension (mm) |

575x575x230 |

765X510X230 |

1000X520X230 |

1175X575X230 |

Other |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

||||

|

Fan |

AC / EC |

||||

|

Input |

220ACV/50HZ/1P |

||||

|

Speed (m/s) |

0.45m/s±20% at high speed |

||||

|

Control type |

Manual / RS485 |

||||

|

HEPA Height (mm) |

50 / 70 Optional |

||||

|

HEPA filter material |

Glass fibre |

||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||

|

Operating temperature |

10~40℃ |

||||

|

Structure type |

Split type |

||||

|

Installation mode |

Horizontal / Vertical |

||||

4.FFU parameters(High speed type ):

|

Model |

High speed type |

|||

|

FFU dimension (mm) |

430X430X270 |

1175X575X270 |

1175X175X270 |

Other |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|||

|

Fan |

AC / EC |

|||

|

Input |

220ACV/50HZ/1P |

|||

|

Speed (m/s) |

1m/s±20% at high speed |

|||

|

Control type |

Manual / RS485 |

|||

|

HEPA Height (mm) |

50 / 70 Optional |

|||

|

HEPA filter material |

Glass fibre |

|||

|

HEPA efficiency |

H13 / H14 /U15 |

|||

|

Operating temperature |

10~40℃ |

|||

|

Structure type |

Split type |

|||

|

Installation mode |

Horizontal / Vertical |

|||

5.FFU parameters(Special type ):

|

Model |

F-DA190X1-SUS304-400X400X100-F50H13 |

F-DA190X1-SUS304-430X430X120-F70H13 |

|

FFU dimension (mm) |

400 X 400 X 100 |

400 X 400 X 120 |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|

|

Fan |

AC |

|

|

Input |

220ACV/50HZ/1P |

|

|

Speed (m/s) |

0.25m/s±20% at high speed |

|

|

Control type |

Manual |

|

|

HEPA Height (mm) |

50 / 70 Optional |

|

|

HEPA filter material |

Glass fibre |

|

|

HEPA efficiency |

H13 / H14 /U15 |

|

|

Operating temperature |

10~40℃ |

|

|

Structure type |

Split type |

|

|

Installation mode |

Horizontal / Vertical |

|

HEPA filter parameters

|

HEPA grade |

H13 |

H14 |

U15 |

|

HEPA eff. |

99.99%@0.3um |

99.995%@0.3um |

99.9995%@0.3um |

|

Material |

Glass fibre |

||

|

Frame material |

Aluminium alloy |

||

|

Net cover |

High quality steel baking paint (double-sided) |

||

|

Gasket |

High density synthetic rubber |

||

6.FFU parameters(3 speed type )

|

Model |

3 speed type FFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

1350X400 |

1470X400 |

Other |

|

FFU material |

Powder coated |

||||||

|

Fan |

AC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

Manual / RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Split type / Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||

7.FFU parameters(3 speed room side replacement type ):

|

Model |

3 speed room side replacement typeFFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

1350X400 |

1470X400 |

Other(其他) |

|

FFU material |

Powder coated |

||||||

|

Fan |

AC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

Manual / RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||

8.FFU parameters(EC energy saving type EC节能型):

|

Model |

EC energy saving type FFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

875X575 |

1010X610 |

Other(其他) |

|

FFU material |

Powder coated |

||||||

|

Fan |

EC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||